Selection Guide for Different Zirconia Materials

2024-11-18

2024-11-12

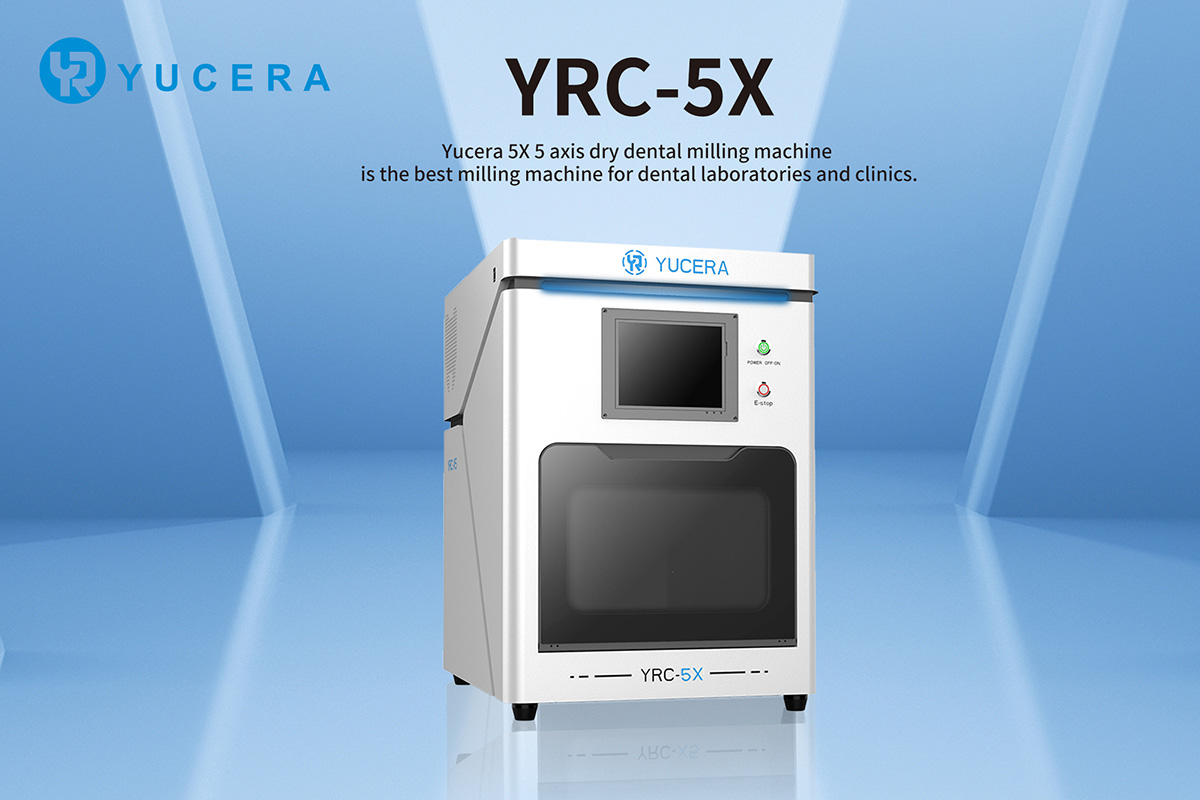

In the field of modern dentistry, the dental carving and milling machine is increasingly prominent. It can accurately process a variety of dental restorations, such as crowns, bridges, etc., to provide patients with more beautiful and comfortable oral restoration solutions. However, with the many brands and models of dental engraving and milling machines on the market, how do you pick a dental engraving and milling machine that's right for you? Here are some key considerations.

I. Machining accuracy

Processing accuracy is the primary consideration in selecting a dental milling machine. A high-precision engraving and milling machine can produce a more suitable for the patient's oral cavity restorations, improve the restoration effect.

1.Spindle precision

Spindle is the core component of the engraving and milling machine, its accuracy directly affects the processing accuracy. High quality spindle should have high speed, low vibration and small runout.

2.Motion system precision

The motion system of the engraving and milling machine includes X, Y, Z three coordinate axes and rotary axes. The accuracy of these axes determines the dimensional accuracy and shape accuracy of the machined parts. High-precision motion system should use linear guide and ball screw, positioning accuracy should be within 0.01mm.

3.Repeat positioning accuracy

Repeat positioning accuracy refers to the accuracy of the engraving and milling machine in multiple repetitions of the same position. High repetitive positioning accuracy of the engraving and milling machine can ensure the consistency of batch processing. Generally speaking, repeat positioning accuracy should be within 0.005mm.

II.Processing efficiency

Processing efficiency is also an important factor to consider when selecting a dental milling machine. An efficient engraving and milling machine can shorten the processing time and improve productivity.

1. Spindle speed

The higher the spindle speed, the higher the processing efficiency. The spindle speed of dental engraving and milling machines on the market today is generally between 30,000 rpm and 60,000 rpm. When choosing, you can determine the appropriate spindle speed according to your own processing needs and budget.

2. Tool switching speed

If the engraving and milling machine has automatic tool change function, then the tool switching speed is very important. Fast tool switching can reduce downtime during processing and improve processing efficiency. Generally speaking, the tool switching speed should be within 3 seconds.

3. Control system response speed

The response speed of the control system directly affects the machining speed and accuracy of the engraving and milling machine. Fast response control system can deal with processing instructions in a timely manner, so that the movement of the engraving and milling machine more smoothly, improve processing efficiency.

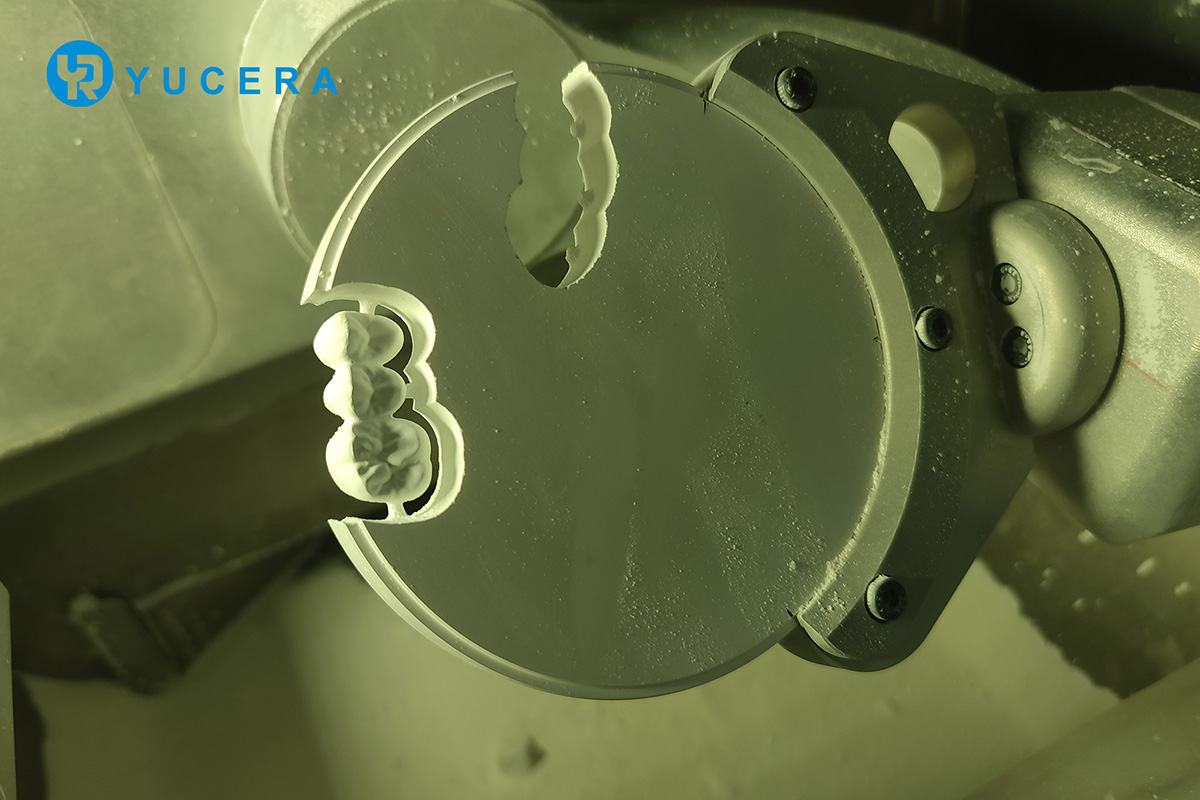

III.Processing material adaptability

Different dental restorations require the use of different materials, so the selection of dental engraving and milling machine need to consider its adaptability to various materials.

1.The type of material

Dental carving and milling machine should be able to process a variety of dental materials, such as zirconia, resin, wax, titanium alloy and so on. When choosing, you can check the material list provided by the manufacturer to understand the machining capability of the engraving and milling machine for different materials.

2.Material size

According to your own processing needs, choose the engraving and milling machine that can process the right size material. Generally speaking, the dental engraving and milling machine processing range should be within 100mm in diameter and 50mm in height.

IV.Equipment stability

Equipment stability is to ensure the processing quality and productivity of the key. A stable engraving and milling machine can maintain high precision and high efficiency in a long time of operation.

1.Body structure

Engraving and milling machine body structure should use high-strength materials, such as cast iron, cast steel, etc., and has good rigidity and shock resistance. The stability of the body structure directly affects the machining accuracy and surface quality.

2.Electrical system stability

The stability of the electrical system directly affects the reliability of the operation of the engraving and milling machine. High-quality electrical system should use well-known brands of electrical components, and has over-current protection, overheating protection and other functions.

3.Cooling system

Cooling system is very important for the stability of the engraving and milling machine and processing accuracy. Good cooling system can take away the heat generated in the process of machining in time, reduce the temperature of the tool and workpiece, reduce thermal deformation and tool wear. The cooling system should be water-cooled or air-cooled, and has enough cooling capacity.

V.Brand and after-sales service

1.Brand reputation

Choose the dental engraving and milling machine of a well-known brand, its quality and performance are more guaranteed. Manufacturers of well-known brands usually have strong technical strength and rich production experience, and can provide users with better quality products and services.

2.After-sales service

After-sales service is an important factor to consider when selecting a dental engraving and milling machine. High-quality after-sales service can solve the problems in the process of equipment use in a timely manner, reduce equipment downtime and improve production efficiency. When choosing, you can understand the manufacturer's after-sales service system, including after-sales response speed, the technical level of maintenance personnel, whether to provide spare parts and so on.

In short, selecting a dental engraving and milling machine for yourself requires comprehensive consideration of factors such as processing accuracy, processing efficiency, processing material adaptability, equipment stability and brand after-sales service. Only by choosing a dental engraving and milling machine with excellent performance, reliable quality and perfect after-sales service, can we bring higher productivity and better economic benefits for dental clinics or processing factories.