How long do zirconia all-ceramic dental crowns last ?

2024-09-20

2024-09-26

To extend the machine's lifespan and reduce milling machine maintenance costs, daily maintenance of dental dry milling machines is essential. Here are a few daily maintenance tips for dental dry milling machines.

1. Dust cleaning

Work chamber: After each day's processing, promptly clean the dust in the work chamber. Use a brush to sweep the dust together, then use the manual page to open the dust extraction function and clean it. For wax dust, it is recommended to use a vacuum cleaner to clean it thoroughly.

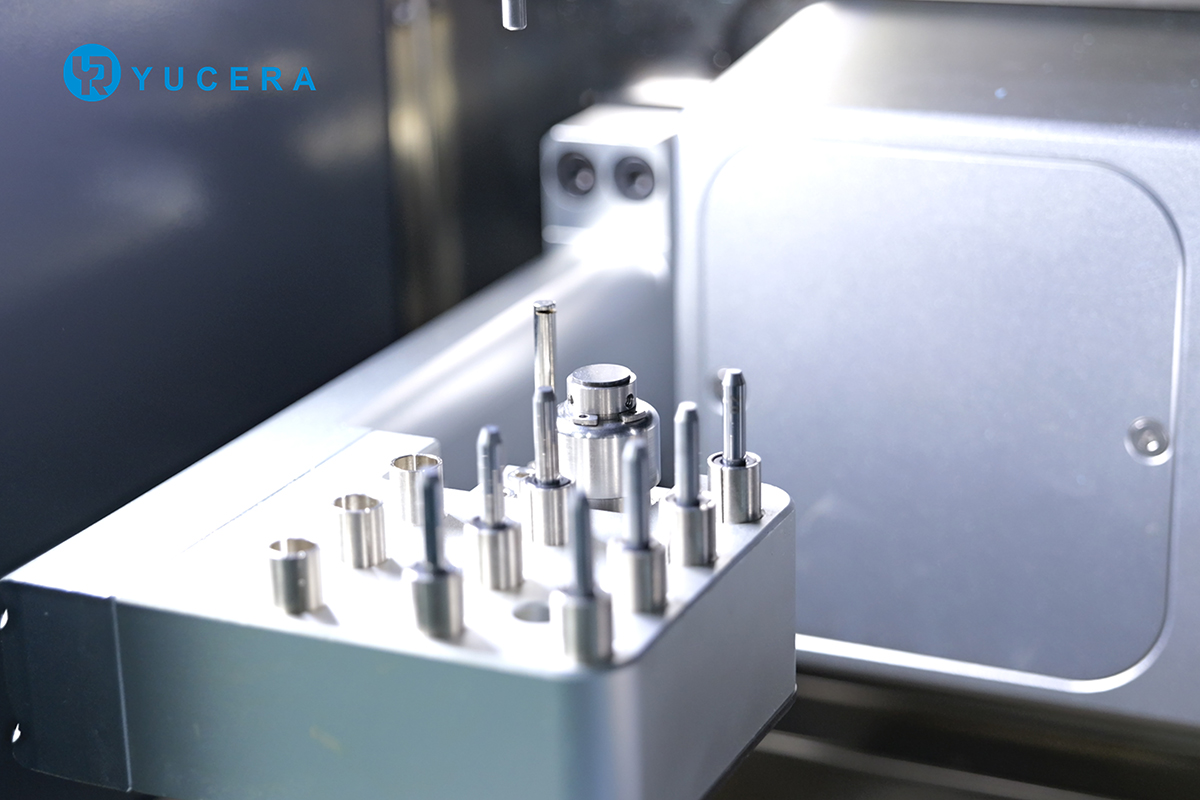

Milling machine: After each day's processing, clean the dust on the milling machine, focusing on the tool library area, the front and rear rotating shaft unit areas, the surface of the Y and X-axis bellows cover, and the bottom area of the processing chamber.

2. Vacuum cleaner maintenance

Regularly (monthly) check the dust in the vacuum cleaner bucket and clean the dust in the bucket and on the filter; regularly check the filter, and replace it if the filter is not breathable.

3. Bur life check

Open the CNC software's tool management to check the usage of each bur. When the bur usage reaches 100%, pay attention to the bur's condition and promptly replace it to avoid chipping or tool breakage.

4. Collet maintenance

Use the CNC software to move the spindle to a removable position, then click to release the tool, use a collet wrench to turn the collet counterclockwise to loosen it. After loosening the collet, use a lint-free cloth and alcohol to wipe the collet taper surface and the spindle inner hole, ensuring no dust or moisture remains.

Click to learn more: /demo/